Manufacturers of cars are always trying to make the best cars so the industry is very complicated and constantly changing. Automakers must carefully plan their operations using efficient methods and high-quality materials to make safe, reliable cars that meet customer needs. This guide will review the steps used to make cars so you can get a sense of what this industry is like.

| Process | Description |

| Design and Engineering | Creation of the car and its parts, including the engine. |

| Materials | Selection of materials based on performance. |

| Stamping | Metal sheets are cut and stamped into car parts. |

| Welding | Joining body parts to create the car’s frame. |

| Painting | Application of prep, base coat, and clear coat. |

| Assembly | Installation of engine, transmission, chassis, etc. |

| Quality Control | Testing to ensure safety, speed, and quality standards. |

| Final Inspection and Shipping | Last examination before transport to dealers or consumers. |

What Is Manufacturing Automobiles?

It is part of designing and putting together all the car parts people want to buy. There is a lot of competition in the car business so companies have to be smart about how they make their cars. The process of making cars is vast and complicated. They are starting with how the vehicle is designed and going through production and test runs. Design production and assembly are usually used to break this process down.

The Design Process

A complete plan for the car has to be made by automobile experts before it can be built. This includes choosing the car’s general shape and size, functions, engine safety features, and other parts that go into making a car. This plan has to meet the wants of customers as well as the rules for the car business.

The Manufacturing Process

As soon as the plan is complete, the production part of making cars starts. This means making bits and pieces and putting them together for a car. Auto companies use high-tech tools to help with this process. One example is an automobile casting press, which takes raw metals and shapes them into car parts.

Assembly Procedure

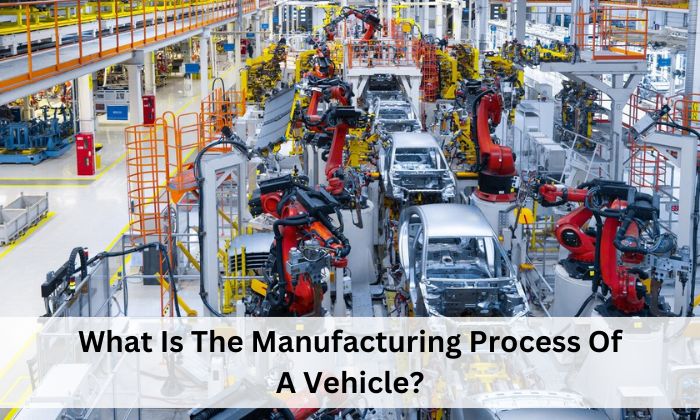

The building method is the last step in making an automobile. Putting together parts and pieces to create a whole car is what this is all about. Advanced robotic arms and other tools are used in auto plants to ensure that vehicles are built quickly and correctly.

Types Of Auto Manufacturing

There are different types of companies that make cars. As a producing business, you need to figure out which way works best for you. For some examples of the most common ways to make cars, here are some:

Mass Production

Many similar cars are made using assembly line methods in this type of auto-making, which is the most popular worldwide. Standardization and technology are used in this method to boost performance and cut costs.

Lean Manufacturing

Lean manufacturing methods focus on increasing efficiency and lowering waste by making the production process better all the time. This means making it easier for materials to move, making the best use of tools, and giving workers the power to find and fix problems. Lean production tries to raise output, lower costs, and boost quality by focusing on these areas.

Just-in-time Manufacturing

This method stresses the importance of only sending materials and parts to the assembly line when needed instead of keeping them in stock. This saves money by reducing waste and making more room in the plant.

Customization

This method is based on making cars specifically planned to meet the requirements of each customer. You can customize many things from choosing specific features and choices to creating your body shapes.

Flexible Manufacturing

This method is meant to work for many different car models and types and the production process can be quickly changed. Flexible production is excellent for making small amounts of specialized cars or adapting to changes in the market.

Manufacturing Processes For Automobiles

The exact steps to make a car can differ based on the car type and the maker’s actions. Nevertheless, the general steps that are usually taken to create a car are listed below:

- Design and engineering: This includes creating the car and engineering all its parts, such as the engine sensors and safety features.

- Materials: The steel metal plastic and other materials used to build cars are carefully chosen based on their power weight and other qualities.

- Stamping: A car’s roof hood doors and sides are made by cutting and stamping metal sheets into different shapes.

- Welding: The body parts combine to make the cars frame.

- Painting: There are three steps to painting the body a prep a base coat and a clear coat.

- Assembly: The engine transmission chassis and electronics are just a few parts of making a car.

- Quality control: Several tests and checks are done on the car to ensure it meets the safety speed and quality standards the maker sets.

- Final inspection and shipping: After passing all the quality control tests the vehicle is examined again before being transported to dealerships or consumers.

These steps only cover some of what you need to know to build a car. Also companies may use slightly different tools and methods or processes.

Conclusion

The business that makes cars is very complicated and competitive, so companies that make cars must be agile and able to adapt quickly to changing customer needs. By using a low-code platform, automakers can get powerful digital tools that can help them save time and money while streamlining their production processes.

FAQs

What Is Automobile Manufacturing?

Automotive manufacturing entails developing and assembling all components to meet client requests and industry standards.

What Is Involved In The Design Process Of Making Cars?

The car’s form, size, functionalities, engine, safety features, and other components are planned throughout the design to suit client needs and industry requirements.

What Are The Main Steps In The Manufacturing Process Of Automobiles?

The primary procedures are design, engineering, material selection, stamping metal sheets, welding body pieces, painting, assembly, quality control testing, and shipment inspection.

What Are Some Common Types Of Auto Manufacturing Methods?

Mass production, lean manufacturing, just-in-time manufacturing, customization, and flexible manufacturing prioritize efficiency, waste reduction, and client demands.